If you’re in the eCommerce business, you’ll likely come across the MOQ abbreviation when sourcing products.

What is the MOQ meaning? Why does it matter?

The short answer is that MOQ stands for minimum order quantity.

It’s an important metric for both buyers and sellers alike. It determines whether or not you can afford to transact with a business.

In this article, we’ll get to the gritty details of MOQ, including the following:

Different types

Benefits

MOQ vs. EOQ

Optimization tips

I’ll also discuss how to calculate your minimum order quantities and price them properly to earn a profit.

Let’s start.

What Is the MOQ Meaning?

A minimum order quantity (MOQ) refers to a certain quantity you have to order per transaction. You can’t order below the minimum amount, but you can order up to the maximum quantity (if there’s any).

MOQ affects all businesses, including manufacturers, suppliers, and eCommerce businesses.

What does MOQ stand for in business? Is it different in manufacturing?

While MOQ stands for the same thing across the board, it has different roles.

Let’s explore how MOQ affects different industries.

MOQ: Supply Chain

The supply chain starts with the manufacturers and suppliers.

The MOQ meaning in supply chain is their ideal purchase quantity, preventing customers from buying products in smaller quantities.

What is MOQ in manufacturing? Why do they have minimum order quantities?

I’ll explain it in more detail below.

MOQ: Manufacturing

Manufacturers and suppliers try to maintain a low price for their products to remain competitive. To achieve that, they have to ensure a profit from every order.

A manufacturer considers the costs of raw materials and producing products. The overall production costs are usually lower for bulk purchases. The bigger the order, the higher the profit margin.

However, MOQ is different from a sample order.

Manufacturers also offer sample orders, which are often in small quantities. They provide potential customers with a way to test their products before buying in bulk.

MOQ: Supply

When you have a business, you’ll have to deal with a supplier’s MOQ.

Some manufacturers can also supply to businesses, but they often stick to manufacturing for suppliers.

These suppliers sell the products to businesses or consumers with a minimum order requirement. They usually set the prices they acquire from manufacturers.

While manufacturers deal with raw materials, suppliers handle the logistics and administrative costs.

Some suppliers also sell retail and entertain direct-to-consumer orders. The price is usually higher, but they may offer discounts if you reach their ideal quantity of order.

What Does MOQ Mean in Business?

If you’re an eCommerce business, there are two ways to approach a minimum order quantity. Either you want the most products for a certain price or a lower price for a fixed number of products.

Ideally, you should know your target profit margins to determine a fair minimum order quantity.

Here’s an example.

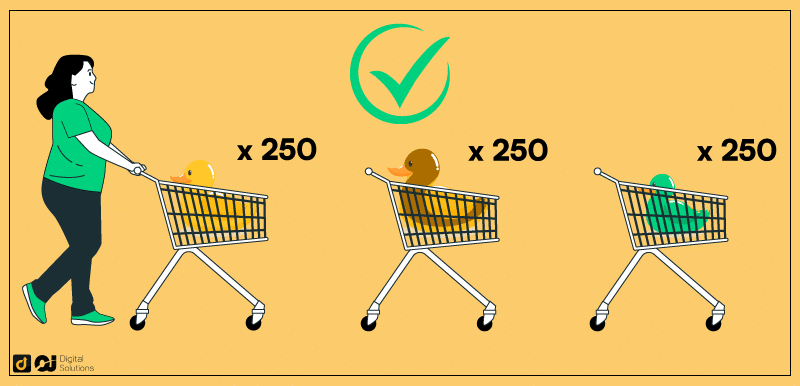

Let’s say you’re trying to buy rubber duckies and want to sell them at $5.

You can look for a manufacturer that can sell you 1,000 rubber duckies for $2, which would cost you $2,000.

or

You can look for a manufacturer that can sell you 100 rubber duckies for $2.50 each, which would cost you $250.

A higher minimum order quantity means you spend more, but you also save more per unit. However, selling 1,000 rubber duckies is also challenging. Space, energy, and inventory management may incur additional costs.

On the other hand, a lower minimum order quantity has lower upfront costs, but each unit is more expensive. However, selling 100 rubber duckies is easier than selling 1,000 units.

Ultimately, it’s important to assess customer demand, sellability, and the desired profit margin to know your ideal minimum quantity.

Different Types of MOQ

Suppliers may implement simple or complex restraints, depending on the type of products they sell.

Their products can either have a simple or complex MOQ. Here’s the difference between the two.

Simple MOQ

A simple MOQ refers to a single lower limit. A supplier may impose either a minimum order value or quantity.

This type of MOQ usually has simple metrics. Goods with little to no variations fall under simple MOQs.

An example would be an MOQ of 1,000 units or $2,500 worth of rubber duckies without any variation.

Complex MOQ

A complex MOQ has two or more limits. Suppliers might impose multiple requirements to the point it can get complicated.

Complex MOQs can take time to negotiate, plan, and agree for both parties. The exchange only happens when both parties agree to each other’s demands or they reach a compromise.

For example, a supplier may have an MOQ of 1,000 units and $2,500 worth of duckies at the same time. You’ll have to meet both requirements to place an order.

It can be more complex than that. The MOQ could further involve a minimum quantity per color, minimum sizes, and a minimum spend.

How Does MOQ Affect Sellers and Buyers?

Whether you’re a seller or a buyer, you need to determine the perfect MOQ based on your budget and needs.

MOQ for Buyers

Smaller-scale businesses like startup e-commerce sites often look for suppliers with a low MOQ. Buying small quantities allows them to test the market and minimize inventory issues.

A low MOQ has other benefits for buyers:

Lower inventory costs

Lower inventory levels

Lower lead times

However, a low minimum order quantity also has a higher per-unit price. A more cost-effective solution would be to buy large quantities.

You can negotiate with the seller for a lower price per unit if you order more than the MOQ.

However, some suppliers don’t sell higher than a minimum amount to new buyers. You’ll have to develop a loyal relationship with your supplier first.

Most wholesale suppliers or manufacturers that only deal with a high MOQ only deal with larger companies.

If you order a higher quantity, you’ll have to deal with larger warehouse space, involving more challenging inventory management and higher holding costs.

I recommend dealing with a high MOQ supplier if you already have a streamlined system.

Consider your budget, as well. Although you can save money by buying in bulk, you’ll incur energy costs and labor costs. If you have a low inventory turnover rate, your expenses will grow higher.

MOQ for Sellers

Sellers have to consider the minimum order quantity they set for their products. This determines what type of customers they deal with.

A low MOQ brings more customers. You can foster more buyer and supplier relationships, which could result in more cash flow.

If you have a high MOQ, you’re targeting large-scale businesses.

For example, you’re selling buttons to big clothing brands. This usually calls for a high minimum order quantity, which ensures a higher profit margin with the average order.

Most suppliers with a high MOQ focus on developing a solid relationship with businesses and retailers. They usually establish their name in the industry first before imposing higher MOQs.

If you’re a new supplier, consider offering a low MOQ first. Although profits may be lower, you’ll get more chances of building a working relationship with businesses.

Difference Between MOQ and EOQ

EOQ stands for economic order quantity, which is another metric businesses should consider.

MOQ refers to the minimum number of purchases you can make. Economic order quantity refers to the minimum order needed to meet demand while avoiding excess inventory-related expenses.

Simply put, EOQ is the most efficient value. While a seller needs to calculate MOQ, a buyer must calculate EOQ.

What Are the Benefits of Minimum Order Quantity (MOQ)?

Suppliers and buyers can maximize the minimum order quantity in different ways. Let’s how they’re different.

For Suppliers

Cash Flow

As a supplier, an MOQ helps create a predictable cash flow. Instead of dealing with micro-transactions, you can estimate regularly based on contracts. If new buyers come in, you don’t need to make huge adjustments.Inventory Costs

Having an MOQ helps you lower inventory costs through proper space allocation. You can easily calculate the space of your warehouse and make way for new orders or reserve space for older orders.If you don’t use inventory management software, having an MOQ gives you an easier way to handle sales data.

Profit Margins

An MOQ gives you more control over the profit margin. Although you’ll lose individual margins since you’re selling in bulk, the volume makes up for it.Fulfillment Costs

Selling one or a few products at a time can quickly drain all your resources into the fulfillment process. The packing and delivery costs quickly add up.Setting a minimum purchasing quantity helps you consolidate orders and minimize shipment costs.

Customer Acquisition Costs

With an MOQ, you don’t have to target every individual. You can spend less money on acquiring customers because you only need a few to keep your business running.Keeping existing clients is also less expensive than getting new ones. Make sure to nurture your business relationship with every client.

For Buyers

Bulk Savings

Even with increased requirements on storage and inventory, buying in bulk lets you set higher margins. Without an MOQ, you can’t get bulk discounts, which affects your average order value.As long as you keep your average storage cost low, you’ll still reach your target gross profit margin if hit your ideal unit sold.

Supplier-Customer Relationships

If you plan to do business long-term with a manufacturer or supplier, it helps to build a healthy supplier-customer relationship. You’ll sometimes get priority. More than that, the supplier or manufacturer will do their best to ensure they deliver.Administrative Costs

You can enjoy lower administrative costs because you don’t have to order products as often. You ensure the availability of your products or materials, and you can prevent supply chain and stocking issues from affecting your operations.

How To Calculate MOQ

While the minimum order quantity formula differs depending on the business or industry, the standard procedure involves these four steps.

Knowing the Demand

Holding Cost Calculation

Determining the Break-Even Point

MOQ Confirmation

1 – Know the Demand.

If you’re already active in the industry, review your internal data to see how many orders you get.

Otherwise, you can look for existing referential data from the web. You can also look at previous market studies or reports on the product you want to sell.

Some people also ask the manufacturer or supplier themselves. Try to ask about their average order volume for businesses in your industry.

2 – Calculate Holding Costs.

How much does it cost to store inventory?

If you’re ordering small-sized items, you might not have to worry much about space and storage costs. For bulkier items, you’ll have to review your inventory storage options.

The product type determines several other costs, including special equipment for handling and storage.

For example, storing meat requires freezers, which incur electricity and maintenance costs.

3 – Find the Break-Even Point.

Breaking even means your total revenue is equal to your cost. Find out how many units you need to sell to break even.

Here’s a quick example.

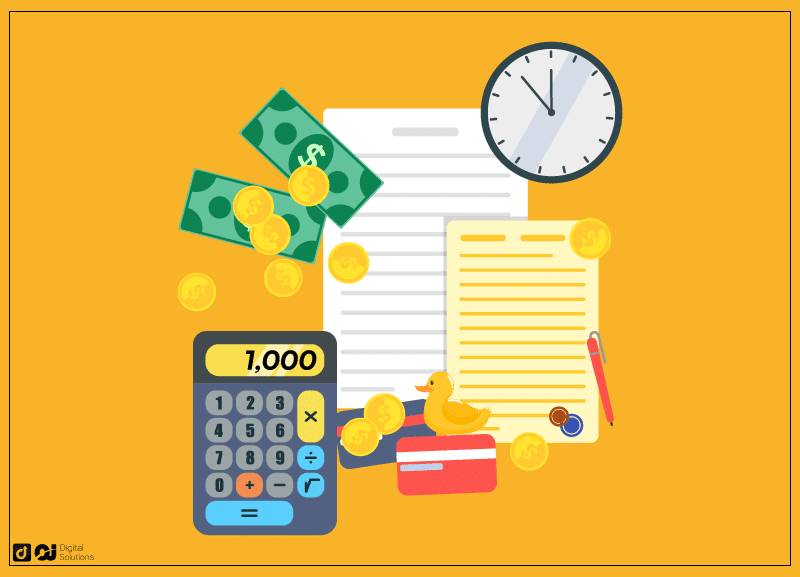

Let’s say producing 1,000 rubber duckies cost you $2,000 in total. You’re planning to sell each for $5.

Let’s also assume there are no other costs. You’re producing and storing the products in your garage, and buyers pay for shipping costs.

How many rubber duckies do you need to sell at $5 each to recover your $2,000 capital?

In this scenario, you need to sell 400 units at full price to break even.

Finding your break-even point allows you to create a strategy to cover your costs and generate a gross profit. This also lets you assess how much risk you’re taking.

However, calculations aren’t as simple since you should also consider labor, electricity, and other associated costs if you want more accurate data.

4 – Calculate Minimum Order Quantity (MOQ).

Once you know how much you sell, how much it costs to store your products, and how many units you need to sell to break even, you can calculate your MOQ.

What’s the minimum quantity order that will keep your business running and generate revenue?

Here’s a simple minimum order quantity example:

1,000 rubber duckies cost $2,000 to produce ($2 per unit).

You want to sell each unit at $5.

The processing cost for every order is $100.

Factoring in these numbers, you need a minimum number of 35 rubber duckies in one order to break even.

This would put the package price at $170, covering the $70 production costs and $100 processing costs.

Your MOQ should then be higher than 35 units to generate a profit.

You can set a low MOQ to attract customers. You can also offer deals and discounts, such as lowering the per-unit cost to increase average order values. The more they order, the more they can save, and the higher your profit.

Factors that Affect MOQ Calculations

It’s easy to focus too much on the basic formula while forgetting other factors can affect your calculations.

Here are some things you should keep in mind.

Product quality and rate of error

Product specifications, including size, design, and color

Shipping location and logistics

Manufacturing process and timeline

Resource availability and reliability

Manufacturer’s or supplier’s production capacity

MOQ Pros and Cons

Should you set an MOQ for your products?

Aside from its benefits, make sure you know some potential drawbacks, as well. Here are a couple of things to consider.

Customer Roadblocks

If you’re targeting small-scale businesses, it can be more difficult to set an MOQ. They’re more cautious about ordering in bulk, especially when transacting with a new company.High Entry Barrier

Setting an MOQ, wholesale prices, and bulk-buying discounts can look appealing on paper. However, new players in the industry will likely encounter some financial challenges early.For example, you need a large inventory to fulfill your orders, which means a higher capital. Buyers are wary about new suppliers, which means low inventory turnover at the start.

Tips to Optimize MOQ

Offer Incentives

With your MOQ as the base point, offer incentives to your customers when they place larger quantities. Increase the average order value by offering more discounts as they order more units.Eliminate Slow-Selling Options

Assess your product’s performance and remove the slow-selling ones. They don’t contribute much, and they take away focus, resources, and space that you could have used for high-demand products.Free Shipping Thresholds

Entice buyers by offering to waive the shipping cost. Offer free shipping on orders that meet the minimum dollar amount, like $ 1,000 worth of rubber duckies.Strengthen Relationships

Build a strong foundation for your customers, and they’ll keep coming back to you. Enhance their customer experience whenever possible, and you’ll earn their loyalty.

Minimum Order Quantity FAQ: Other Things You Should Know

Effect of MOQ on Inventory

The higher the MOQ, the more space you need to store your inventory. This also depends on the size and space your items need.

How To Use Inventory Management Software

Inventory management software lets you configure your minimum order quantities, track inventory levels, and set up automated reorder notifications.

The software also provides valuable data for reviewing your products’ performance. You can adjust MOQs based on supplier capabilities and customer demands.

How To Negotiate for Lower MOQ with Chinese Suppliers

Chinese suppliers offer lower prices, but making business with them can be harder due to language and distance barriers. You won’t likely get your ask right away.

When you like a supplier’s service, you can start fostering a long-term partnership. Stay loyal and gradually increase your order volume, then ask to renegotiate your contract.

When To Use MOQ

MOQ applies to industries where manufacturers or suppliers don’t necessarily sell directly to consumers. This gives way to bulk buyers who can then resell to individuals.

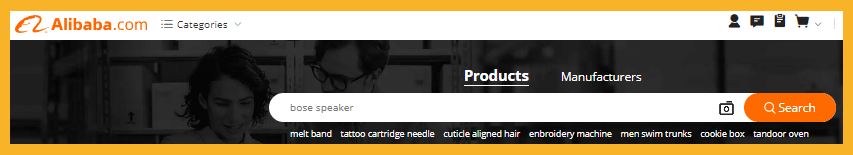

MOQ Meaning, Alibaba Platform

Alibaba is an online marketplace connecting manufacturers to suppliers and businesses. It’s China’s largest B2B online marketplace that caters to every part of the world.

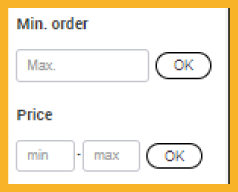

On the platform, MOQ refers to the minimum number of units you can buy from a seller. However, the platform sometimes allows you to buy a sample before you purchase in bulk.

Frequently Asked Questions

Why Do Suppliers Have High MOQs?

Suppliers have high MOQs because they’re looking for a different clientele. These sellers prefer selling high-volume orders to a few customers compared to fewer units to more customers.

What Is MOQ vs. SPQ?

MOQ refers to the minimum number of units you have to order. SPQ means standard pack quantity, which refers to the minimum number of units you can order in one package.

How Do I Find Manufacturers With an MOQ I Can Afford?

For certain platforms like Alibaba, you can filter results by putting your desired minimum order. It’s an easy way to compare prices and find a reliable supplier.

The Bottom Line

I talked about everything you need to know regarding MOQs.

Before setting an MOQ, do your market research. Your every business decision is to meet customer demand.

If your MOQ is too high for your audience, it will be challenging to get customers. You’ll also miss potential long-term business relationships.

If selling to retailers is something you find overwhelming, consider selling wholesale on Amazon. However, you’ll still have to set an MOQ.