If you’re interested in learning more about WMS, you likely have these questions.

What does WMS stand for, or what does WMS mean?

What is WMS software?

What is WMS in logistics?

What is an example of an inventory management system?

What is the process flow (warehouse management system)?

A WMS is a system to help you control various warehouse variables.

However, there’s far more you must know, which is why I wrote this article.

I’ll discuss everything about warehouse management systems.

Let’s begin.

Warehouse Management System Definition: What Is a Warehouse Management System?

The simplest explanation is a warehouse management system (WMS) helps you manage your warehouse. You can use WMS to describe everything regarding your warehouse management.

Furthermore, a warehouse management system (WMS) is a set of policies and processes for warehouse facilitation or management.

This system consists of rules, procedures, boundaries, and protocols you follow to manage your warehouse management processes.

It’s also the umbrella term for specific elements of inventory management, supply chain management, labor management, and other activities necessary for a warehouse.

Warehouse management systems vary by company, meaning there isn’t a one-size-fits-all solution.

However, there are principles of the warehouse management system that you can use for every industry. You can also use different system components, like WMS software, to improve your work.

Warehouse management systems have these levels of complexity.

Basic WMS

Advanced WMS

Controlled WMS

Basic Warehouse Management System

Basic warehouse management systems handle inventory management and location control. It lets you know when to restock but not how much resources you spend.

A good sign of a basic warehouse management system is inventory accuracy. You can achieve accuracy with automation through basic warehouse management system software.

Advanced Warehouse Management System

An advanced warehouse management system tracks resources like time and labor spent on various activities.

You can use advanced WMS systems to learn more about your supply chain operations. At this level, your WMS system overlaps with your warehouse control system or warehouse execution system.

A high-performance, advanced warehouse management system provides sufficient data for financial decisions on labor and other factors.

Controlled Warehouse Management System

A controlled WM covers information outside the warehouse, like transportation, customer orders, and manufacturing needs.

With controlled warehouse management software, you can automate your warehouse operations and streamline your arrival, processing, and delivery procedures.

What Is WMS Software?

WMS software is part of the WMS ecosystem.

WMS software houses the system and tells it how to operate.

You use the system through the software to access data, carry out commands, or update protocols.

What Is WMS in Logistics?

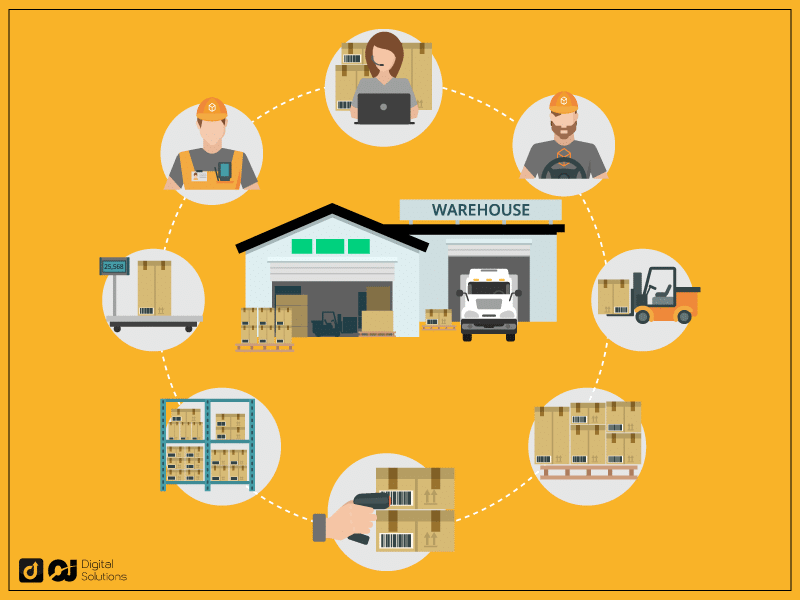

WMS in logistics involves handling everything inside your warehouse, from the arrival of your shipments to their departure.

However, a more extensive WMS can show you data outside the warehouse, like shipping, transportation, and order fulfillment.

Why Do You Need a Warehouse Management System (WMS)?

Here are the benefits of WMS solutions for businesses.

Improved Pick-ups and Put-aways.

With excellent warehouse management, your systems will reduce unnecessary time wastage within your warehouse.

Designated sections for each item let you streamline warehouse processes from arrival to delivery.

Accurate Inventory

Warehouse management solutions give you accurate inventory information to help you make executive decisions, like when to slow down or ramp up sales efforts.

Cost Savings

Automation helps you save on warehouse operations. It also prevents lost packages, misplaced items, unaccounted stock, and other factors adversely affecting your business operations.

Shipment Accuracy

Warehouse management systems help you meet customer demand by ensuring accurate shipping.

Types of Warehouse Management Systems

Warehouse operation management systems are complex networks.

If you don’t know the difference between one system and another, you might end up with a system incompatible with your warehouse or distribution center.

Here are the different types of systems.

Standalone Systems

This system only handles functions inside the warehouse space.

Supply Chain Module Systems

This system covers your supply chain, including vendor relationships, business processes, risk evaluation, and the general WMS solution.

Enterprise Resource Planning (ERP) Systems

An integrated ERP system includes accounting, financials, customer relationships, and inventory management.

ERP systems handle more of your WMS and help communicate information from your warehouse to other business sectors.

On-Premise Systems

These systems use warehouse management software you install on-premise to help you manage everything within the warehouse. Some companies prefer this system because they have more control over it and because it keeps their systems private.

Cloud-Based Systems

A cloud-based solution is often a software-as-a-service (SaaS) solution that manages everything on the cloud.

You upload, process, and analyze data on the cloud instead of in-house hardware.

Warehousing Management System Software Features

Here are the different features you’ll find in WMS software.

Warehouse Design

This feature lets you customize workflow logic to ensure optimal warehouse functions. In turn, you’ll maximize storage and speed up the inventory process.

For a complex supply chain process, you must customize each software segment to match your system and modify variables like arrival time, section interaction, and warehouse protocols.

Inventory Tracking

This is an essential feature you’ll find in most WMS software.

Tracking inventory is crucial, so look for software with an intuitive user interface (how the software or app looks and performs) that shows complete data.

Inventory tracking involves looking past your stock. If you’re dealing with perishables, learn each item’s logistics processes.

You must have real-time data visibility of your inventory and the ability to carry out commands through the software. Instead of manually giving orders to your warehouse manager to accomplish a task, you can instruct your WMS system.

Instead of overstocking and spoiling goods, you can set automatic purchase orders when vacancy reaches a certain level.

Receiving and Putaway

This process in inventory management gives everyone real-time visibility of the items’ locations. It has pick-to-light or pick-to-voice technology to help locate items within your warehousing operation.

Pick-to-light systems make items or sections of your warehouse light up whenever you need their location.

Pick-to-voice systems involve voice commands and alarms to help you determine an item’s location.

These systems help your fulfillment capabilities, especially if you have multiple warehouses and need to locate your order. You save countless hours by eliminating the need to check shelves or warehouse segments individually.

Picking and Packing

Wave picking and batch picking are two modes you can enter with your warehouse software to track which items are ready to ship or leave your facility.

Your system should also visually represent shelves or warehouse segments in the packing phase.

Shipping

Warehouse systems also let you send bills of lading (B/L) before shipping to generate shipment packing lists and invoices and automate the notification process.

The bill of lading is a legal document from a carrier to a shipper that includes product information like product type, quantity, and destination. It’s also a required receipt when shipping products.

A bill of lading protects you against package theft. It lets you know the item was in the facility, received a B/L, and disappeared after exiting your warehouse.

Labor Management

Warehouse software also helps you evaluate your staff through key performance indicators (KPIs). You can determine who is underperforming and who is the best at their jobs.

You can also track lousy performance. If you keep losing packages, your WMS software can tell where they disappeared, what happened, and who was responsible.

You can also program your software to notify when warehouse workers underperform or underperform consistently for a specific period.

You can let HR receive notifications and issue a protocol for underperformers.

Yard Management

Warehouse software helps you handle your inbound and outbound logistics by giving you transportation management systems.

If you deal with a high volume of trucks arriving and deploying, yard management helps you manage them. You can track their schedule, order volume, and other information like a driver’s identity and destination.

Yard management lets you prepare through automation. You can use this system to receive notifications or schedules of inbound trucks to ensure you pack the right items before their arrival.

This system should ideally calculate the time it takes to prepare orders or shipments and ensure they are ready to go when the truck reaches your warehouse.

Reporting

Besides micromanagement, WMS helps you with macro-management.

It gives you reports on your warehouse’s performance throughout a specific period.

You can gain business intelligence, like where you spend most of your time and other factors affecting profit, including overhead, labor costs, storage availability, and overall efficiency.

If you have shareholders or board members, WMS software gives you the data necessary to create a monthly, quarterly, or annual report.

Your software can also give warehouse managers weekly reports for faster problem-solving.

With real-time inventory visibility and periodic reporting, you can make critical decisions by cross-referencing real-time and historical data.

You deal with a significant amount of data when you use a WMS. You may need the best data visualization tools to show data and highlight trends or complex data sets accurately.

Who Uses WMS?

WMS is not just for warehouse owners. It’s for an organization that deals with receiving, storing, and shipping out stock.

Here are the different types of users for the WMS system.

Manufacturers

Manufacturers need WMS because they deal with various products and raw materials. The system becomes more sophisticated if your facility manufactures multiple products.

WMS allows manufacturers to view their inventory and output without overwhelming them by providing a smart way to see different aspects of your production, from material components to labor performance.

These systems help manufacturers organize shipment and delivery schedules critical to your WMS supply chain. You’ll get notifications when resources are low and program the WMS to carry out actions like automatically ordering new materials if your component inventory hits a specific level.

Distributors

Distributors need WMS technology to help improve order management accuracy.

Even if you deal with millions of orders, you’ll have information on each one.

A WMS is vital if you deal with multiple locations and schedules.

If you handle multiple products, you need a system to track them individually and properly organize orders under their respective title.

You can also group items into categories for simplified viewing. If you work with multiple warehouse managers, you can design your software to give them access to only specific product or category details.

Retailers

A WMS system is present in multiple brick-and-mortar stores. Retailers benefit from this system because locating items is often challenging, especially with limited space.

Instead of manually looking for a pair of shoes, you can quickly type the item code to see if it’s available.

Retailers can also use WMS software to make restock decisions whenever product stock is low. You can set customized limits per product and instruct the software to send notifications whenever it reaches that level.

Ecommerce Companies

Ecommerce companies rely on WMS systems because the business owners or managers aren’t always at the warehouse to check if they have a particular product.

Due to the lack of physical access, they must use the software to get real-time visibility and data representation for their entire supply chain.

The software enables ecommerce companies to track items when they arrive or if they are in the packing or ready-to-ship stage.

Besides visibility, the system gives you speed when handling your warehouse remotely.

Instead of calling in and telling a specific person to accomplish a task, you can give commands through your system and direct them to everyone or a specific person. You can also use your WMS to access third-party logistics to know more about the state of your packages.

Example of Inventory Management System(s)

Katara is an example of an inventory management system for manufacturers. It helps you keep track of raw materials, production, and shipments.

Here are other examples of WMS inventory management system software solutions.

List of WMS Software

Here are some of the best WMS software.

Frequently Asked Questions (FAQs)

WMS Definition or WMS Meaning: What Is It?

WMS means warehouse management system. You use a WMS to manage warehouse activities and handle deliveries, shipping, or labor.

What Is WMS Experience?

The WMS experience is the system you get with WMS software. It lets you review data, input commands, and adjust protocol.

Is Warehouse Management System Functionality Worth It?

Yes. It’s worth it if you deal with high-volume, multi-product inventories. You might not need this system if you only deal with one or a handful of products.

Is WMS a Type of ERP?

No. A WMS is a standalone solution for warehouse operations, while an ERP is a comprehensive solution for all your business activities, from sales to marketing.

What Is KPI in WMS?

KPI means key performance indicators that let you track your processes to see if they meet specific goals and objectives.

What Is a WMS Tool?

A WMS tool is the app or software you use to access your system. This tool lets you view data, make commands, or modify processes.

The Bottom Line

I hope my guide gave you all the information you need on warehouse management systems. If you’re starting to use a warehouse, look for the most straightforward software and scale as your system gets more complex.

Don’t hesitate to try out different software before committing to one.

If you want to build a physical space to store your products, learning how much it costs to build a warehouse is ideal.